- KAIZHENG

- CHINA

- A ser confirmado

- Suficiente

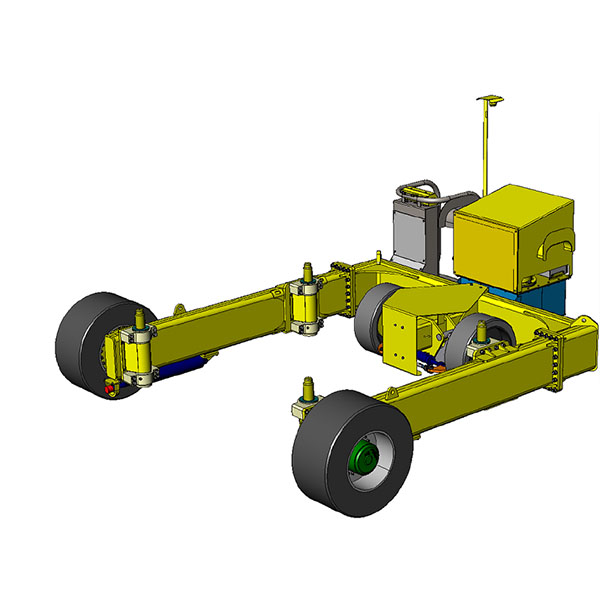

Transportador de calha de alimentação (tecnologia patenteada)

Ferramenta de remoção de revestimento de moinho (tecnologia patenteada)

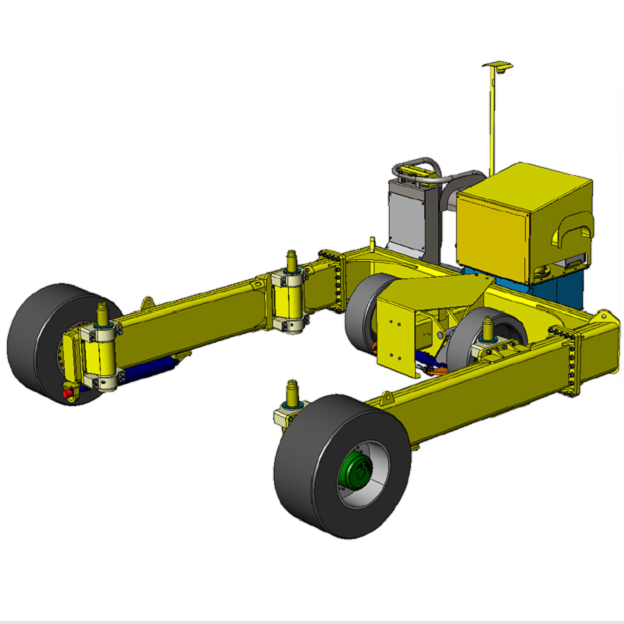

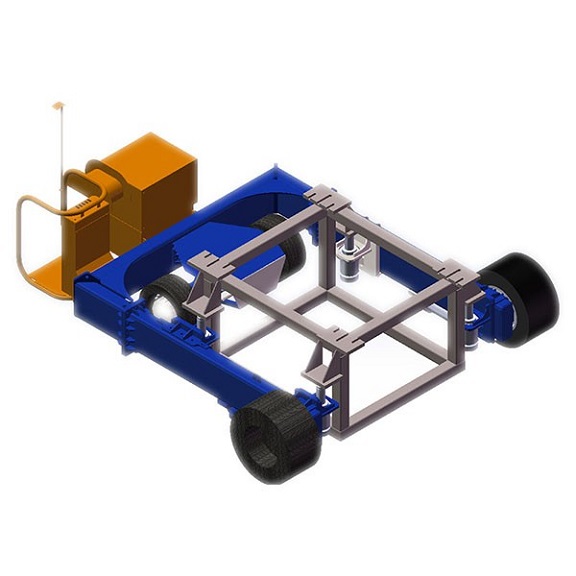

Feed chute transporter (Patent technology)

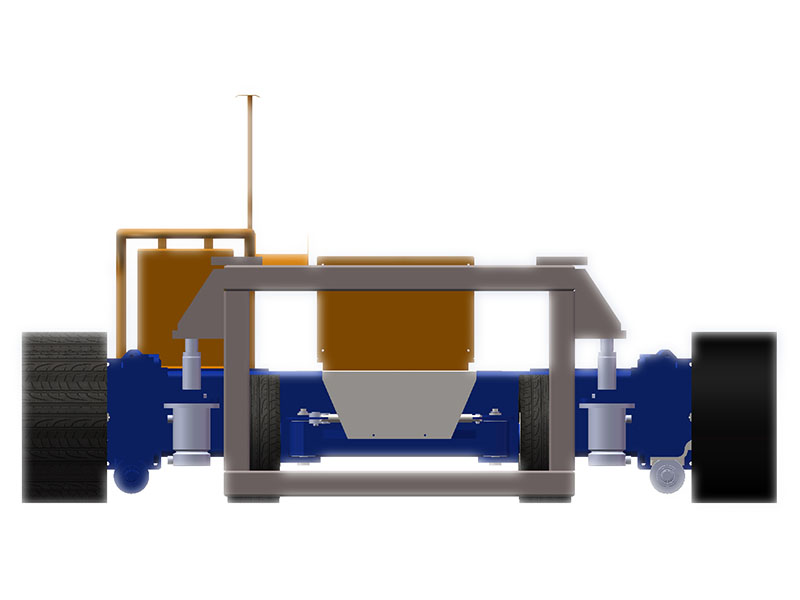

This equipment is mainly used for conveying the feeding chute of a specific grinding machine to facilitate the maintenance of the machine. It can seperate the feed chute and the mill. After the internal maintenance is finished, the feed chute will be sent back to an appropriate position as before. The feed chute is designed according to the different specifications of the mill.

Basic principles:

When the equipment is powered on, the front wheel bears the main load and the rear wheel is mainly used for steering. The front wheel is composed of a complete gearbox and a hydraulic motor. The feed chute can be easily taken off under the work of a jacking hydraulic cylinder.

Safety of transportation:

The equipment is equipped with an emergency stop button, which can be pressed immediately if any fault is found in the transportation process. Reset the device before it restarts.

Braking:

The brake is installed in the gearbox of the two driving wheels. The brake will stop the machine immediately if there is a fault, as the hydraulic power will cut off and the transport vehicle will stop.

Sound-light alarm:

When there is a fault, the sound-light alarm will be activated automaticly. The system gets reset until the fault is eliminated.

Hydraulic system with over-pressure protection:

The main hydraulic pump adopts built-in pressure compensation and pressure relief valve, which limits the pressure in the hose. The control valve group has the integral pressure relief valve. The key protection measures are forbidden to be modified.

Hydraulic control:

All hydraulic levers are loaded into neutral position with a spring. Operation is stopped when the lever is in neutral position.

Hose cover:

All hoses are secured and covered reliably to avoid the damage from hydraulic hose cracking.

Balance valve:

All cylinders are equipped with a balance valve. When the hydraulic system displays fails or stops, it will be locked in the last set position. If the hydraulic pipeline breaks, all hydraulic movements will stop in that particular circuit.

Power failure:

Once there is a power failure will cut off the hydraulic pressure supply, then all the hydraulic movement will stop. The balance valve will keep it in the final set position, when the pressure is back to normal, the equipment movement will not automatically restart, unless operation is recovered.

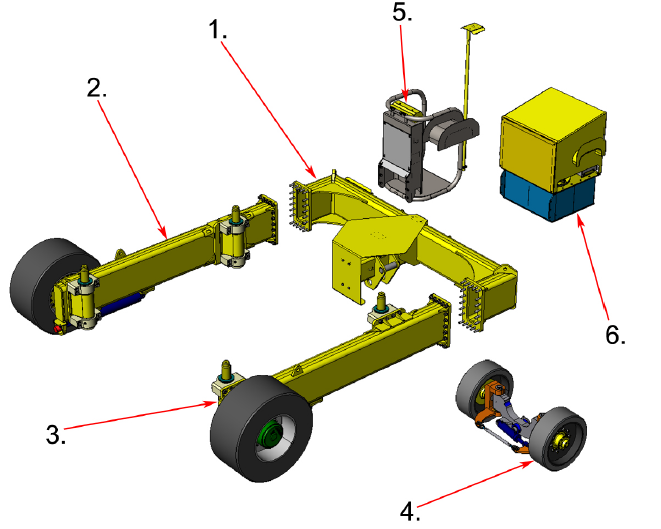

Struture:

1----Torsion beam assembly 2----Right side assembly 3----Left side assembly 4----Rear axle and steering wheel 5----Operator station 6----Hydraulic power unit

Frame:

The frame is used to transfer the load from the jacking device to the wheels. It is composed of torsion beam, left assembly and right assembly. There are jacking jacks at the front and back, and the wheels and steering gear are installed on the assembly on each side. The operator station will drive the device close to or away from the mill.

Rear axle and steering wheel

Rubber tires are used for working on general mixed soil or asphalt pavement road. The ingenious design of structure meets the characteristics of heavy load. The rear steering rod can adjust the alignment of steering, and rear steering cylinder is managed by the controller, to achieve turning and adjusting the direction etc.

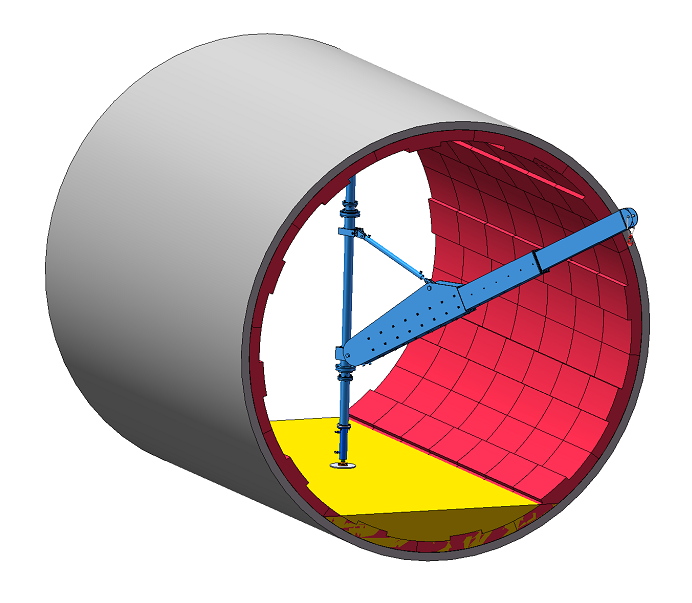

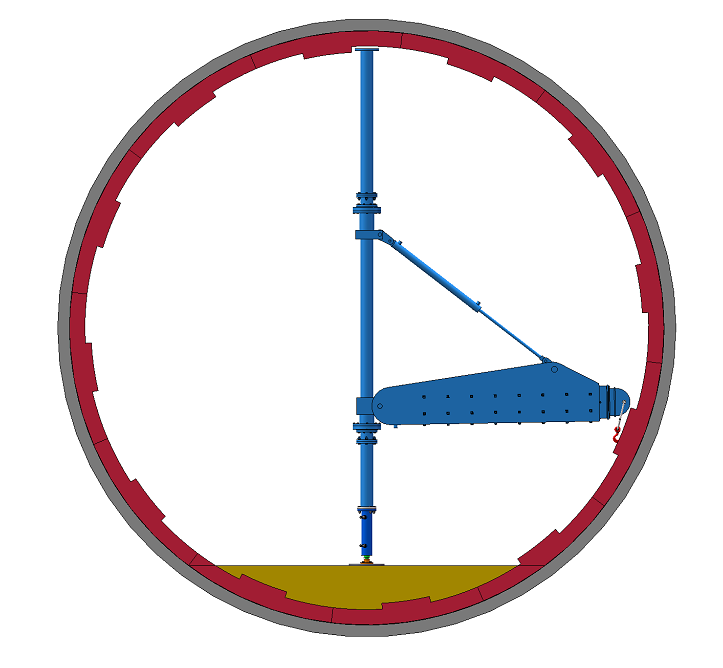

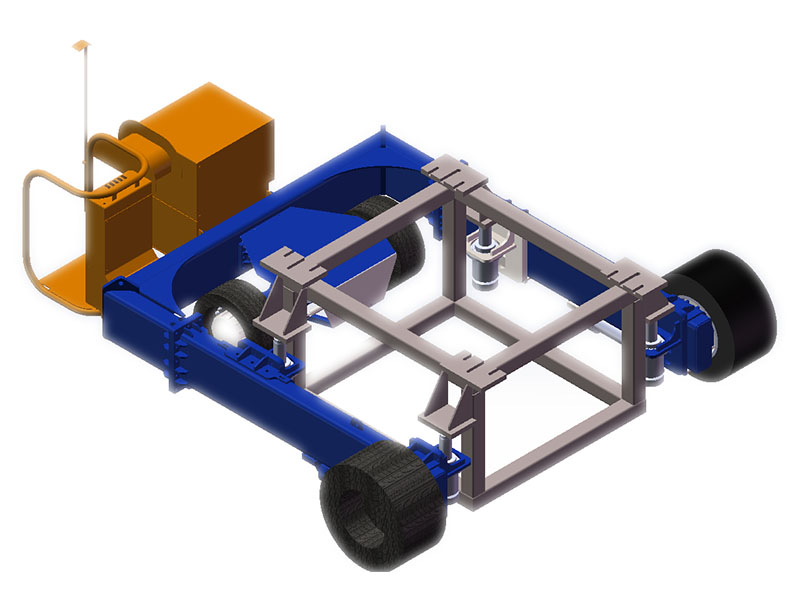

Mill liner removal tool (Patent technology)

The mechanical transfer of mill liner, aims to reduce the labor intensity of workers, and to improve the working environment.

Basic principles and characteristics:

The manipulator can be fixed inside the ball mill through the column, the column can be lifted to adapt to different diameters.

The manipulator can swing up and down around the fixed point to adapt to the disassembly of the lining board in different positions.

The mechanical arm is retractable to accommodate the disassembing at different positions and to remove it to the outside.